Description

The Challenge of Espresso Martinis in Bars and Restaurants

The Espresso Martini is a timeless classic — simple in concept, but tricky in execution. A perfect balance of espresso, vodka, and coffee liqueur creates that signature flavor, crowned with three coffee beans for good luck.

Sounds easy — but in a busy bar, it’s anything but.

Behind the bar, speed and consistency are everything. Pulling a fresh espresso shot, measuring ingredients precisely, shaking for that silky foam, and straining into chilled martini glasses takes time. During that time, a bartender could have served an entire round of other cocktails.

When one customer orders an Espresso Martini, suddenly everyone wants one. That’s when service slows down, queues build up, and stress levels rise. Many smaller bars don’t even offer it — either because they lack an espresso machine or can’t afford the slowdown.

The result? Missed revenue opportunities from one of the most in-demand cocktails worldwide.

The 2025 Solution: The Naiko Espresso Martini Machine

In 2025, the Espresso Martini remains one of the top-selling cocktails in the world — and Naiko delivers the ultimate solution for high-volume venues.

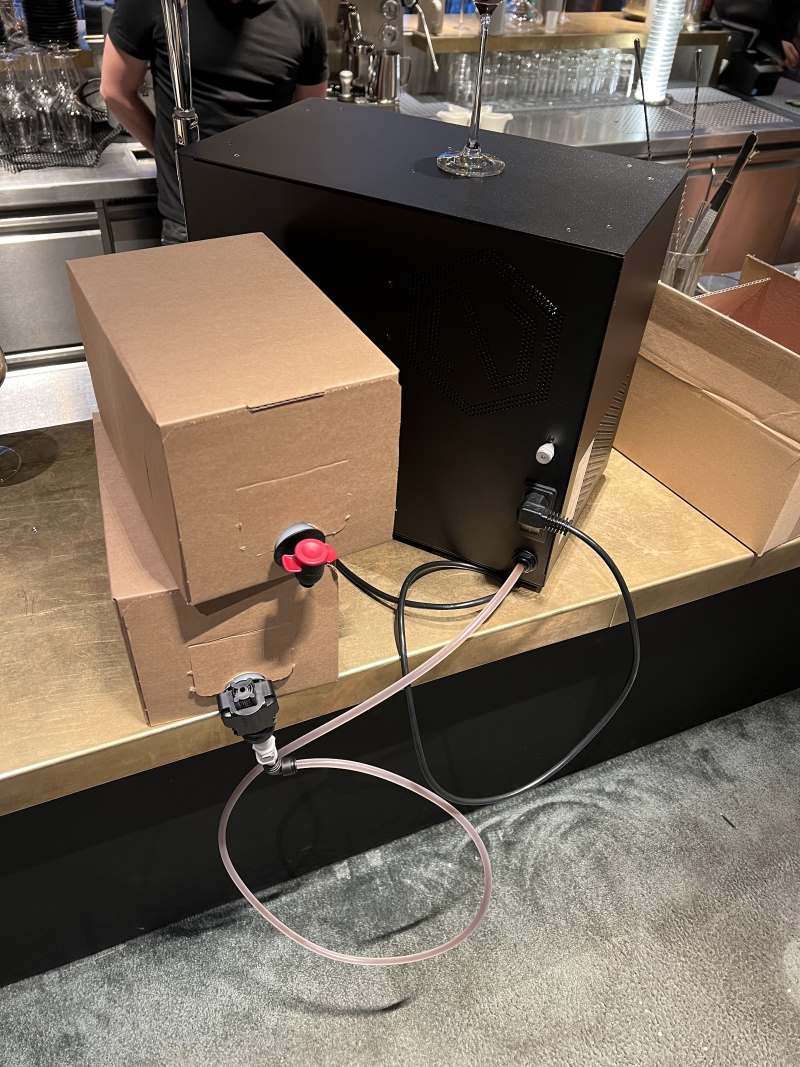

Our Naiko Espresso Martini Machine uses cutting-edge nitrogen infusion technology to serve perfect Espresso Martinis in just seconds. The system infuses atmospheric nitrogen from ambient air at 4 bar pressure, rapidly cooling the drink in an integrated cooling system.

Paired with Naiko’s 10-liter Bag-in-Box pre-batched Espresso Martinis, bartenders can serve consistent, premium-quality Espresso Martinis every time — without shaking, mess, or delay.

The result?

-

Silky texture and natural crema from high-pressure nitro infusion

-

Perfect temperature and consistency

-

Service speed up to 100 ml in just 4 seconds

-

Happier customers — and higher revenue per hour

Naiko enables bars, restaurants, hotels, and event venues to serve premium Espresso Martinis on tap — faster, cleaner, and more profitable than ever.

Who We Are

Naiko comes from the Hawaiian word for Nitrogen — the gas that makes up 78% of the air we breathe. Our entire philosophy revolves around harnessing this natural element to transform beverage experiences.

The idea was born in 2015, when our founder traveled to California and saw the complex, expensive setups needed for nitro cold brew. His vision: to make high-quality nitro beverages simpler, more efficient, and more consistent — without bulky gas cylinders or refrigeration systems.

The Naiko system introduced three key innovations:

-

Integrated cooling — no separate fridge required.

-

Nitrogen from ambient air — no gas cylinders, no refills.

-

Self-priming pump — no manual handling or kegs.

By 2018, our team realized that Espresso Martinis and Naiko Nitro Technology were the perfect match.

Today, in 2025, Naiko systems are operating worldwide — from cafés in Europe to hotel bars in Dubai and beach clubs in Australia. With just a power connection, you can serve perfect nitro-infused Espresso Martinis anywhere.

Why Partner with Naiko?

Naiko is more than a concept — we’re a manufacturer with in-house development and production in Germany.

We design and build our Naiko Nitro Dispensers, and we produce our own cold brew and cocktail recipes, ensuring that every component — from the machine to the mix — works in perfect harmony.

This vertical integration gives us a unique advantage:

-

Full control over technology and quality

-

Custom solutions for hospitality partners

-

Unmatched consistency and reliability

If you’re ready to serve the world’s fastest, most consistent Espresso Martini, Naiko is your partner in innovation. We also offer Nitro Cold Brew Coffee solutions for cafés and hotels.

Contact us to become a Naiko partner.